![]() Current Location:

首页>Product Center>Ruinuo Product

Current Location:

首页>Product Center>Ruinuo Product

Polymer Foam Filling Material for Coal Mine Sealing - Ruinuo Filling Material (CT PF)

Product Description

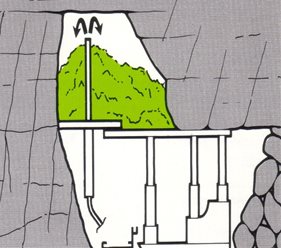

This A/B two-component phenolic resin foam material consists of an A component (a mixture of phenolic resin aqueous solution, inorganic powder, and foam stabilizer) and a B component (composed of organic acid and phosphoric acid). During on-site application, the components are mixed in a 4:1 volume ratio using a two-component pneumatic grouting pump and specialized grouting gun. The product features low reaction temperature, rapid foaming expansion, high-toughness foam solidification with pressure resistance, flame retardancy, and high-temperature tolerance. It effectively fills voids in roof collapses, abandoned areas, and rock surfaces within sealed coal mine shafts, ensuring rapid sealing.

Performance characteristics

Application Scope

Technical Parameters

Product Characteristics

Performance Indicators

Component A

Component B

Appearance

Brown liquid

Dark red liquid

Mixing Ratio /by volume

1:1 or 4:1

Flash Point /°C

>200

Inorganic material, non-flammable

Maximum Reaction Temperature /°C

<90

Foam Termination Time (23±2°C) /s

<120 (or adjustable based on project requirements)

Foam Expansion Ratio

10–30 times

Compressive Strength /MPa

>0.1 (10% deformation), >0.1 (30% deformation), >0.4 (70% deformation)

Compression Deformation /%

>70

Flame Retardancy & Anti-static Properties

Complies with MT113-1995 technical standards for polymer products used in coal mines

Storage and packaging

- The product is packaged in 25L plastic barrel or iron barrel, and the packaging is not recycled.

- The products should be stored in a dry, cool and ventilated place. Sun exposure and direct rain are strictly prohibited. The storage temperature range is 0-35℃. Materials below-10℃ are easy to freeze, so they need to be stored in frost-proof storage.

- Product shelf life, component A shelf life is 3 months, component B shelf life is 6 months.