![]() Current Location:

首页>Product Center>Ruinuo Product

Current Location:

首页>Product Center>Ruinuo Product

Silicate-Modified Polyurethane Foam Material for Underground Engineering Filling - Ruinuo Filling Material (CT PU)

Product Description

This product has obtained the national invention patent (patent number: ZL 2014 1 0835097.8), does not release toxic and harmful gas, large volume application is safe and reliable.

Superior volume stability of cured foam: Compressible and stress-adaptable

Flame-retardant foam with low smoke emission at high temperatures

Ideal for water-bearing conditions (filling, consolidation, leak sealing)

Applications

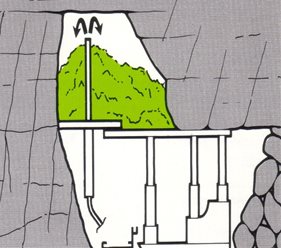

Rapid filling of roof cavities or loose/fractured coal/rock masses in underground engineering

Sealing abandoned cavities (e.g., goafs)

Fracture grouting to prevent air leakage in coal/rock strata

Fast consolidation of karst caves/tunnels to stabilize surrounding rock

Product technical parameters

Product Characteristics

Performance Metrics

Component A

Component B

Appearance

Colorless transparent liquid

Dark brown liquid

Mixing Ratio (by volume)

1:1

Flash Point (°C)

Non-flammable (inorganic material)

>150

Peak Reaction Temperature (°C)

<90

Reaction Properties

Unaffected by water injection; adjustable curing time

Foam Termination Time

10–80 (adjustable per project needs)

Expansion Ratio (times)

10–30 (adjustable per project needs)

Compressive Strength (MPa)

>0.1 (10% deformation),

Compression Deformation (%)

≥70

Oxygen Index

≥35

Flame Retardancy & Antistatic Performance

Complies with MT113-1995 technical standard for polymer products in coal mines

The above data are based on laboratory test results. Actual performance may vary slightly depending on field conditions.

(at 23±2°C, seconds)

>0.1 (30% deformation),

>0.4 (70% deformation)

Storage and packaging

- The product is packaged in 25L plastic barrel or iron barrel, and the packaging is not recycled.

- The product should be stored in a dry, cool and ventilated place, and must not be exposed to sun or direct rain. The storage temperature range is 0-35℃. Materials below-10℃ are easy to freeze, so it should be stored in a frost-proof place.

- The shelf life of the product is 6~12 months.